This article is part of a blog by Genesis, a link to the full article is below.

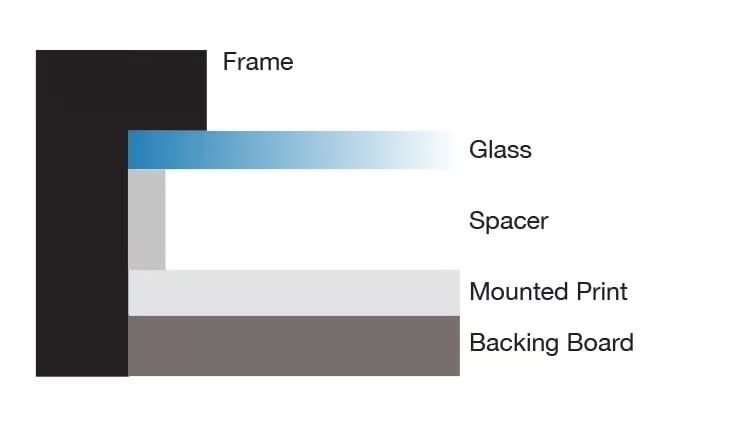

Spacer (Box) Framing

‘Spacer’ or ‘box’ framing uses a ‘fillet’, or ‘spacer’ which runs alongside the inner edge of the frame and provides a separation between your artwork and the glass of the frame.

Alongside the contemporary aesthetic achieved with spacer framing, the separation

between your artwork and the glass of the frame also aids in preventing damage to your prints caused by condensation (which can result in water damage, mould, mildew or the deterioration of the surface of the image).

Spacer framing is also ideal for 3D artworks as we can adjust the depth to accommodate your work.

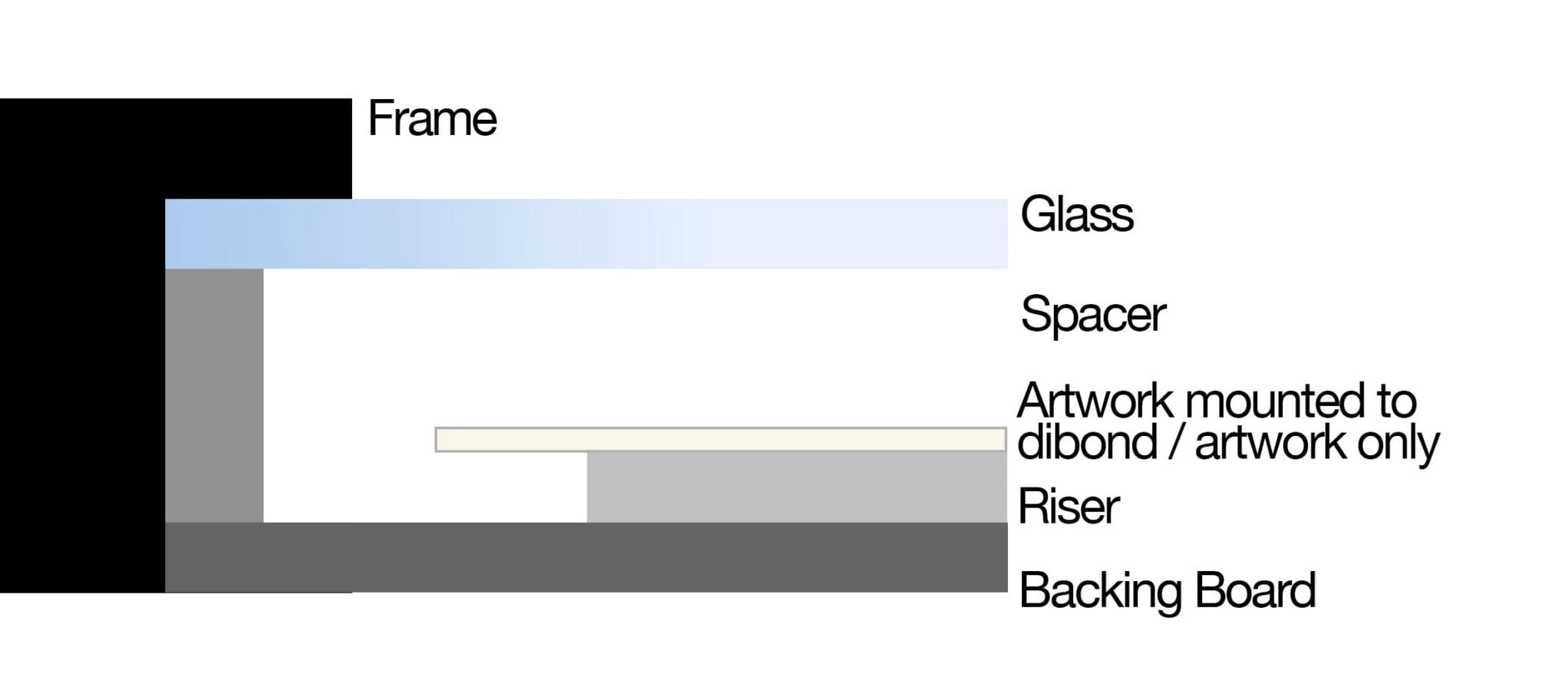

Float (Box) Framing

Float (Box) Framing involves mounting artwork onto a rigid backing, known as a ‘riser’. A gap is maintained between the mounted artwork and the frame moulding, giving the appearance that the artwork is floating within the frame. This method provides depth and separation, allowing the artwork to be presented without direct contact with the frame edges.

Float (Box) Framing gives your artwork a clean, modern look by creating a floating effect within the frame; perfect for adding dimension and highlighting artwork in a contemporary, minimalist way.

The separation between the artwork and the glass of the frame also aids in preventing damage to prints caused by condensation (which can result in water damage, mould, mildew or the deterioration of the surface of the image).

Additionally, instead of mounting your artwork, we can use Japanese hinges to attach it to the backing board of the frame, preserving the archival integrity of your artwork.

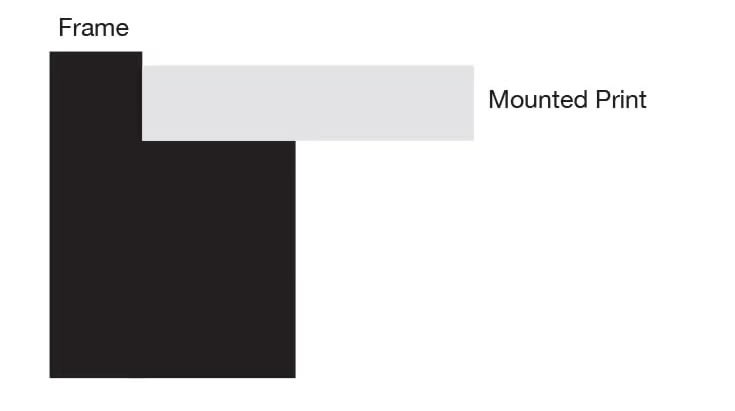

Tray Framing

Tray framing offers a glassless, contemporary framing solution that achieves a 3D, floating’ effect for your images or artwork.

Your images are mounted to Dibond – a lightweight aluminium composite known for its rigidity – which protects the print and provides a firm base for framing. A smaller sub-frame is then attached to the reverse of the mounted print, giving space between the back of the frame and the print. The artwork is set back slightly from the edge of the frame to prevent damage, and there is space left on all sides of the mounted print within the frame to achieve the floating effect.

Keyline Framing

Keyline frames offer a lightweight, glassless finishing option for your photographs and artwork.

Without glass, keyline frames are more lightweight than traditional framing and reflections on artwork are minimal. Keyline frames are a popular solution for those wanting to frame their work without glass.

Your images are first mounted to Kapa Foamboard to ensure they lay flat within the frame and provide extra strength and rigidity. We then paint the edges to match your chosen moulding colour and tone, and the mounted print is attached directly to the frame. The wooden mouldings we use for our framing are from sustainable sources that meet environmental, social and economic needs for both the present and future, as certified by the FSC scheme.

Our frames are available in sizes up to 110 inches or 2.8m, although we can accommodate larger requests on application.

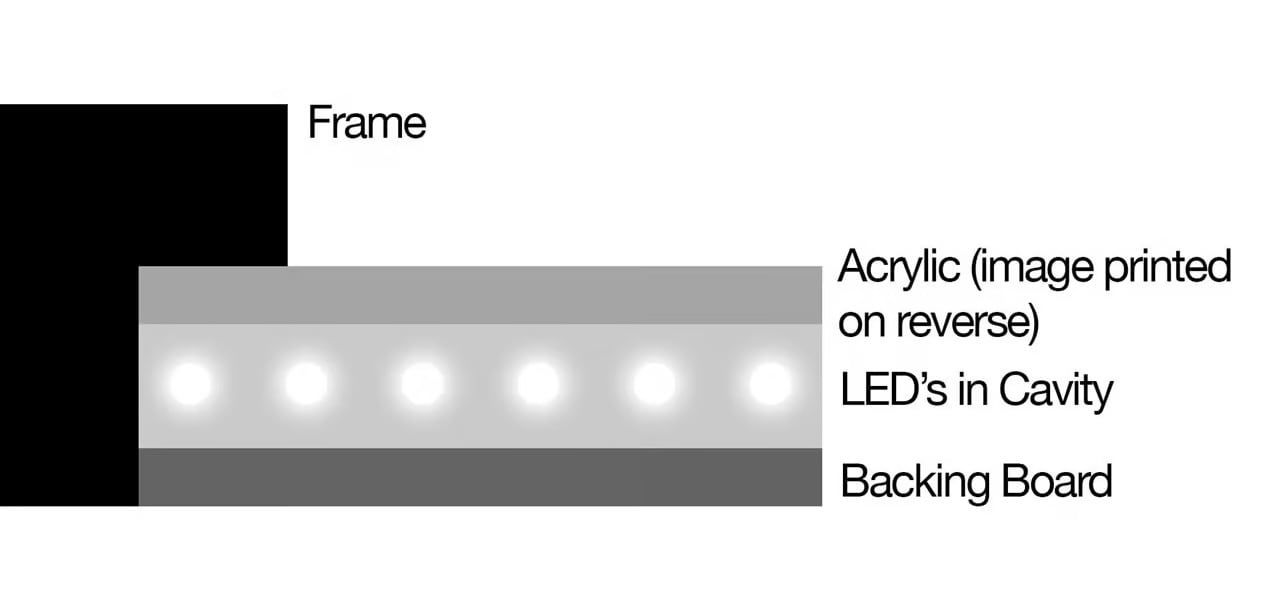

Bespoke Lightbox Framing

We offer exhibition-quality, bespoke lightbox framing to complement our ultra-slimline, lightweight fine art lightboxes.

Our team make lightboxes using a range of exhibition-quality mouldings. We first produce prints as Duratrans, and a diffuser is then used to ensure even light disbursement from the LED panels used within the lightbox.

We use only the highest quality LED panels to illuminate all of our lightboxes – this gives us greater flexibility in the size we can produce and means that our lightboxes are evenly lit from edge to edge.

The change from fluorescent tubing to LED panels also allows us to produce extremely slimline lightboxes to bespoke specifications. LED lighting also emits far less heat than traditional lightboxes, which use fluorescent tubing, which not only requires additional depth to prevent overheating but can result in image deterioration.

The LED light is dispersed through a diffusing layer of translucent Perspex for even illumination.

The first step for producing lightboxes is printing your images; we print these as Duratrans using the digital c-type process – rendering images durable and archival on a translucent base suitable for lightboxes.

This article has been editied, to read the full article click here

https://genesisimaging.co.uk/